Share this

Industrial Blade Maintenance Services: What to Expect from a Qualified Vendor

by Hyde on Nov 24, 2025 8:00:01 AM

The right blade makes all the difference in final product quality. As a leading supplier of industrial knives and industrial knife blades, we understand how to craft a high-quality product that helps you meet your standards every time. But choosing the right blade is only the beginning. You need to keep up with blade maintenance services to protect your investment and keep your blades functioning like new.

Picking the right vendor is just as important as selecting your initial blade. Prepare yourself with the tools needed to vet a provider so you get your blades back in like-new condition.

Why Outsourced Blade Maintenance is Key to Manufacturing Uptime

Regular maintenance prevents unplanned downtime from injuries or equipment failures. It also keeps your final products consistent and improves on-floor safety. It saves you money by maximizing blade life and allowing you to maintain consistent quality.

Dull and damaged blades can tear and cut raw edges. Instead of getting a finished product every time, your team has to fix or dispose of unusable products. Dull blades also require more force to cut, which increases injury risk.

How often should blades be serviced?

The ideal frequency of blade sharpening services depends on your blades and how you’re using them. Consider these factors:

- Hardness of the material you’re cutting: Harder materials, such as wood, plastic, and metal dull blades faster than softer materials, such as textiles.

- Blade material: A high-quality blade made of carbide steel will stay sharp longer.

- Machine hours: If you’re using machines continuously, your blades will wear faster.

Refer to your manufacturer’s guidelines and inspect your blades at the end of the day to look for signs of wear. Track the overall cut quality and the level of effort you need to cut.

What’s the difference between sharpening and reconditioning?

Sharpening a blade involves removing small amounts of material on a blade that’s become dulled. Reconditioning is a full restoration process for damaged blades. This process involves cleaning the blade, stripping the damaged parts, sharpening, and coating.

What Does a Full Maintenance Service Include?

Opting for a full blade maintenance service will extend the useful life of your industrial blades. Since you replace them less often, you can save money while maintaining consistent product quality.

If you opt for a full-maintenance service, expect your vendor to provide:

- Detailed inspection and failure diagnostics: Assess the blade for warping, cracking, or other signs of irreparable damage. If you’re not using our services, a vendor may measure the blade and reference the operating manual for original measurements.

- Blade balancing and alignment checks: Balance and align your blades by adding weight and removing material. We will also determine how to best position the blade on your machine for optimum performance.

- Edge profiling and sharpening to OEM specs: Check the original specs specific to your blade to reshape your knife’s bevel and then sharpen the blade to precise measurements.

- Coating reapplication for wear resistance: Recoat your blades so they are more durable.

- Documentation of work performed: Document the work for your records.

Regrinding Shop or Blade Specialist: What’s the Difference?

A basic grinder only sharpens industrial blade and knife edges. You might get lucky and find a vendor with metallurgy experience who understands how to work with your specific knives. Professional blade maintenance specialists have specialized machines for carbon steel, stainless steel, and coated blades. Blade maintenance specialists with experience in industrial knife blades may also offer services such as granulator blade replacement and slitter blade hardening.

A local shop might use machines that strip coatings or affect your knife’s performance. If you work in an industry with specific tolerance levels, you need to find a qualified vendor who understands how different blade tolerances impact performance. Working with a manufacturer is the only way to guarantee like-new performance.

Key Questions to Ask Before Outsourcing Blade Maintenance

Proper research will help you find a vendor who fits your budget without ruining your blades. Ask your vendor these important questions before handing over your valuable equipment:

- Do you recondition to OEM tolerances or just sharpen? A high-quality vendor will consult your operating manual before removing material from your blades.

- What inspection and quality checks are included?

- Do you provide a turnaround time guarantee?

- Can you diagnose the root causes of premature wear?

- Do you have metallurgical experience?

- What types of materials do you usually work with?

- What certifications do you or your techs have?

- Describe your safety protocols.

- Do you document your work and provide records?

- Describe your quality control methods.

The Risks of Going With the Cheapest Option

When running a business, cost is always a factor, and it figures into how you choose a blade maintenance partner. But choosing the wrong partner can end up costing you in the long term. You might get your blades back with uneven edges that impact overall product quality.

If your vendor removes too much material or doesn’t reshape your blade correctly, you may not be able to put it back in the machine. You may end up losing time and money while you have the blade replaced.

Picking a local vendor with the wrong sharpening and grinding equipment also puts you at risk. If they’re working with the wrong tools for your blades, it could shatter your equipment, which potentially opens you up to liabilities.

Your safest bet is to return your industrial blade to the manufacturer for maintenance services or work with a professional with specialty experience.

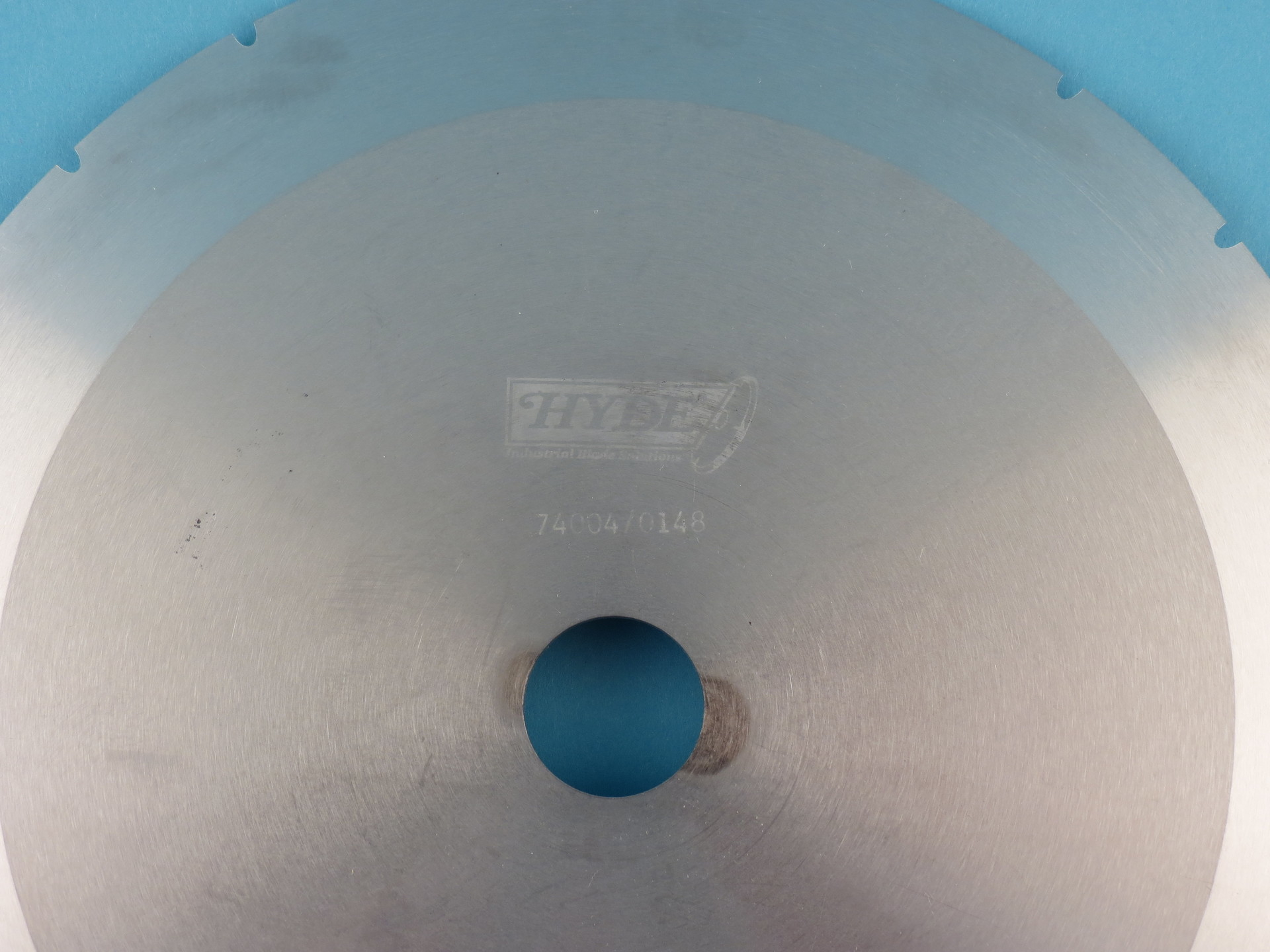

What to Expect From Hyde’s Maintenance Services

Hyde Industrial Blade Solutions is a U.S.-based company with more than 150 years of experience in manufacturing and servicing industrial knife blades. We are skilled at metallurgy and have the right equipment to work on your blades.

We offer quick turnaround times and expert craft skills. We also thoroughly inspect our work and document it for your records.

Improve your blades’ performance and increase their lifespan with regular maintenance. Get a free quote today and view all products on our website.

Share this

- February 2026 (2)

- January 2026 (6)

- December 2025 (4)

- November 2025 (4)

- October 2025 (6)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (2)

- April 2025 (2)

- March 2025 (2)

- February 2025 (1)

- January 2025 (8)

- October 2024 (5)

- September 2024 (3)

- August 2024 (4)

- July 2024 (3)

- June 2024 (1)

- August 2023 (2)

- June 2023 (2)

- March 2023 (1)

- April 2022 (1)

- March 2022 (1)

- January 2022 (1)

- July 2021 (1)

- April 2021 (1)

- March 2020 (1)

- January 2020 (1)

- August 2017 (1)

- May 2017 (2)

- April 2016 (1)

- February 2016 (1)

- January 2016 (1)

- October 2015 (1)