Industrial Slitter Knives & Core Cutters

Clean Edges. Zero Dust. Perfect Rolls.

Precision-ground shear slitters and crush cutters for paper, film, and foil converting. Featuring the American Blade Source catalog of top knives, bottom anvils, and pneumatic holders.

Industrial Slitting Configurations

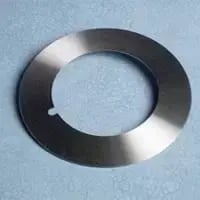

Dish Slitters

Precision-ground top knives with single or double bevels. Available with polished faces to minimize friction and dust when shear cutting paper and film.

Flat Slitters

Versatile rotary shear blades for general web converting. Manufactured from 52100 bearing steel or D2 for maximum edge retention in high-speed lines.

Score Slitters

Heavy-duty crush cutters with radius edges. Designed to score or separate abrasive materials (like sandpaper or tape) against a hardened anvil roll.

Core Cutters

Stop crushing your tubes. Our core knives feature optimized bevel angles to slice through heavy-wall cardboard and plastic cores without burrs.

Bottom Slitters

Matched bottom anvils and multi-groove sleeves. Ground to strict concentricity tolerances to ensure constant contact with the top knife and prevent vibration.

Corrugated Slitters

Razor-sharp serrated and scalloped profiles designed to slice through corrugated board without crushing the flutes or tearing the liner.

Precision Slitting Systems & Converting Knives

- Blade Types: Top Dish Knives, Bottom Anvils (Bands), Score Cutters, & Split Bottom Knives.

- Core Cutting: Polished bevels for burr-free cuts on fiber, plastic, and tape cores.

- Material Compatibility: Paper, Corrugated, Film, Foil, Non-Wovens, & Thin Metals.

- Steel Options: 52100 Bearing Steel, D2, M2 HSS, & Tungsten Carbide.

- Edge Profiles: Razor Sharp (Shear), Radius (Score), & Square Edge.

Stop stopping your line to adjust knife holders. Our matched top and bottom sets are ground to identical tolerances for set-it-and-forget-it performance.

The Hyde Difference

Wide Variety of Options

We offer a wide variety of slitters including dish, flat, score, corrugated, and bottom. Need something different? Let us know and we'll let you know if we can help.

Fast Quote Turnaround

Our full team sits at our US headquarters, enabling us to get you a quote in as little as 24 hours.

Best in Class Lead Times

With standard project lead times averaging 3-4 weeks, we can get you what you need faster than the competition.

In-House Controls

Heat treating, laser cutting, and a high tech quality control lab all in-house allow us to get our customers the highest quality products.

Tight Tolerences For Better Cuts

Our customers depend on high-quality blades. We maintain strict tolerances on flatness, runout, and bevel design to ensure our customers experience superior cutting performance.

Customize Based on Your Needs

With a wide variety of different steel options and the capability to create blades large or small, we can get you exactly what you need.

Get in Touch!

We'd love to help you get a solution based on your needs!