Extended-Life Blades for High-Volume Plastics Processing

Minimize downtime in your granulators, pelletizers, and shredders. We engineer high-wear industrial knives using Solid Steel, Carbide, Stellite, and Ceramic to withstand the most abrasive thermoplastic applications.

-

Applications: Compounding, Extrusion, Recycling, & Blow Molding

-

Compatibility: Drop-in replacements for all major OEM granulators & pelletizers.

-

Lead Time: Custom tooling shipped in as little as 3-4 weeks.

SERVING GLOBAL PROCESSORS

.png?width=300&height=115&name=Americhem(1).png)

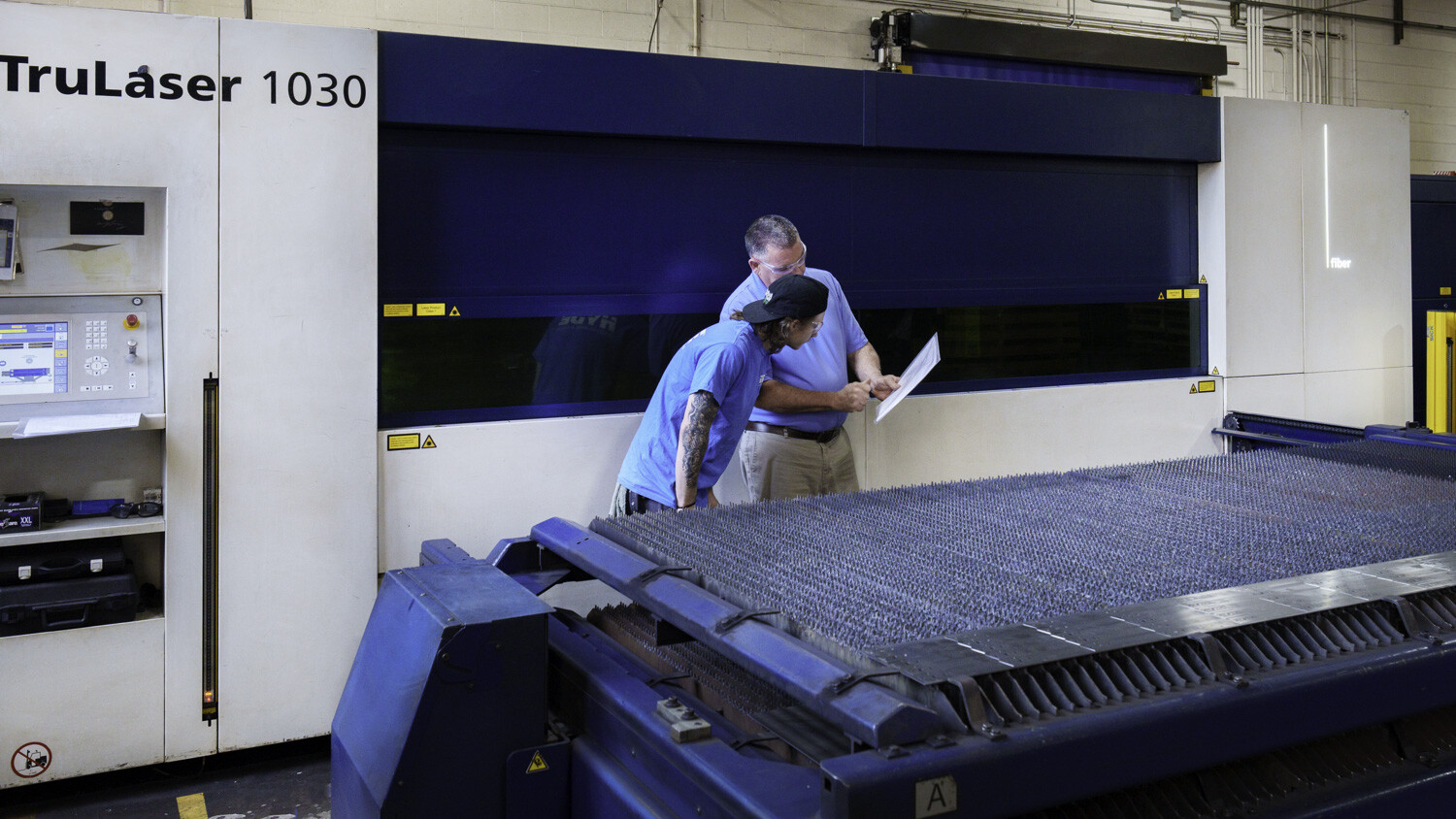

End-to-End Manufacturing Control

Drawing on decades of experience, we supply a full range of pelletizer rotors and knives, blow molding knives, granulator knives, and shredder knives. Our applications engineering team designs tools that last longer and boost productivity, while in-house sawing and laser cutting let us produce almost any shape without costly tooling. Advanced heat treating and premium materials—including steel, carbide, Stellite, and ceramic—deliver the performance today’s processes demand. Hyde knives help increase throughput, reduce downtime, and improve your bottom line with truly cutting-edge performance.

We Produce Every Blade Plastics Processors Need

Pelletizers

Precision strand and underwater pelletizing knives ensuring uniform pellet geometry for high-volume compounding lines.

Granulator Knives

High-wear rotor and bed knives engineered to produce clean, dust-free regrind from scrap bottles, runners, and sprues.

Shredder Knives

Heavy-duty shredder blocks and counter-knives built to withstand high-impact loads during primary size reduction.

Custom Knives

Made-to-order blades for specialized extrusion and molding applications. We manufacture to your exact print or sample.

Get in Touch!

We'd love to help you get a solution based on your needs!