Share this

Mill Knives Explained: Uses, Materials, and Customization Options

by Hyde on Oct 1, 2025 11:45:01 AM

Manufacturing operations are only as good as the blades they use. Strong, precise industrial mill knives are critical to material consistency, uptime, and preventing waste. But how do you pick a great mill knife out from the pack?

In this article, we’ll first define the characteristics of a mill knife. Then we’ll discuss their common applications, the specific design elements to look for in a good model, and the advantages of mill blade customization for industrial cutting tasks.

What is a Mill Knife?

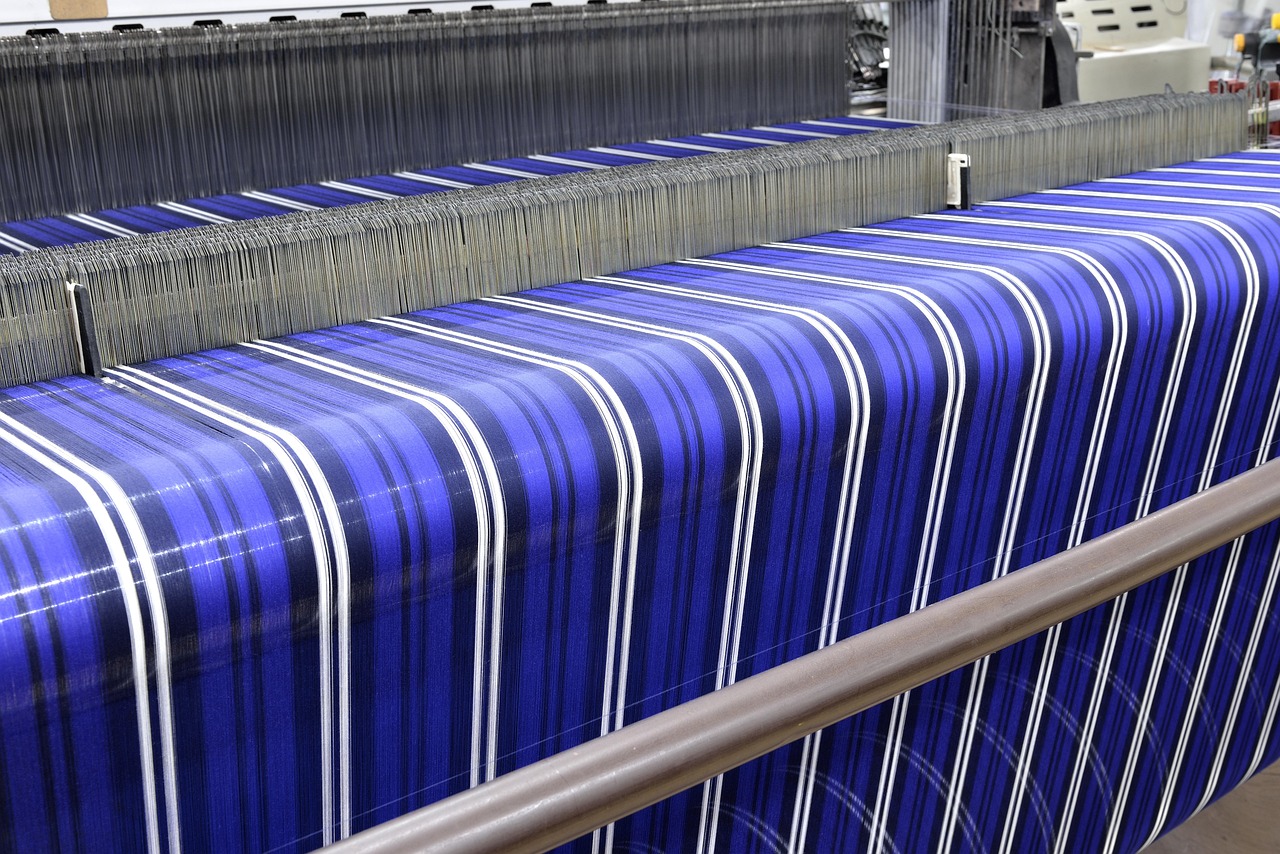

Mill knives (also referred to as mill blades) are used in numerous industries, including leather processing, shoemaking, tire and rubber production, textiles, and plastic film production. While modern industrial heavy-duty mill knife blades are frequently used as hand tools, they’re also engineered to be used for continuous cutting and slitting tasks on high-speed production lines.

One other point worth noting: the term ‘mill knife’ does not mean the same thing as the terms ‘milling knife’ or ‘milling knives’. The latter terms aren’t actually used very often in a formal sense, and when they are, they usually refer to abrasive or cutting milling bits instead of true blades. Despite the term ‘mill’ being part of their name, mill knives are not abrasive tools, but rather sharp steel blades used to execute precision cuts.

Common Applications Across Manufacturing Sectors

One of the most common industrial applications for mill knives is to mount them on adjustable arms in production lines, allowing them to be positioned for high-speed slitting of materials like rubber, plastic film, and textiles. They are also frequently used for trimming excess and unusable material from the edges of materials like leather and rubber. And of course, they also serve countless professionals as critical hand tools, particularly those working in the tire and rubber industry.

To do these jobs well, mill blades need to sustain high-cutting performance over an extended period of use. This includes:

- Resisting material build-up

- Maintaining a consistent edge quality

- Executing consistently precise cuts

When engineered to provide the highest cutting efficiency possible, mill knives help support continuous uptime while minimizing waste.

Key Blade Features That Impact Performance

When choosing the right mill knives for your operation, several features warrant consideration. First, what blade shape will best serve your application? Common mill knife blade shapes include:

- Bevel point: An angled blade with a slope or ‘bevel’ along the angled edge. Commonly used for trimming leather, rubber, and textiles.

- Curve point: A curved blade with a beveled interior edge. Widely used for accurate slitting, trimming, and other industrial tasks on production lines.

- Sharp point: An angled blade with a bevel along the non-angled edge. Favored by manufacturing processes that require high-precision cuts and piercing.

- Lance point: A blade equally angled and beveled on both edges. Favored for high-precision cuts and piercing.

- Square point: A blade with a squared tip equal in width to the rest of the blade and a bevel along one edge. Commonly used for trimming leather and thick textiles.

- V-cut or V-trim: A blade with a V-shaped notch on the end and a bevel along the interior of the notch. Commonly used for materials like plastic film, paper, and foil, as well as for creating angled cuts in thicker materials.

- Hook: A blade with an end that curves or bends more than 90 degrees and a bevel along the interior of the curve. Commonly used for thick, abrasive materials like rubber and carpeting.

Another factor that needs to be considered is the angle of the bevel on your mill knives. Generally speaking, larger bevel angles create stronger, longer-lasting blades, while smaller bevel angles are sharper and produce finer cuts. Typically, thicker and more abrasive materials require larger bevels, while thinner or more delicate materials can rely on smaller bevels.

Choosing the Right Blade Material

Then, of course, there’s the blade material itself. Hyde Industrial Blade Solutions works with many different steel alloys, each featuring different characteristics regarding hardness, wear resistance, and corrosion resistance. Choosing the right one comes down to a specific operation’s needs.

For example, a rubber processor may be looking for mill blades with the best possible edge retention, capable of withstanding high-speed continuous use trimming rubber sheets. For their needs, M2 high-speed steel, a special variety of tool steel, would likely be a good fit, due to its solid balance of toughness and sharpness. This balance would help ensure their blades maintain their edge well under high-volume production conditions.

Off-the-Shelf vs. Custom Mill Knives

When it comes to hand tools, many manufacturing and trades professionals do well with catalog options so long as the catalog offers sufficient variety in terms of handle length, blade length, blade shape, materials, and overall length. However, it’s a different story for machine-mounted mill knives.

Even the most extensive catalog can’t offer sufficient customization options to suit the exact specifications and needs of all industrial operations. That’s where fully custom industrial blade manufacturing comes in.

Why Customization Matters for Long-Term Efficiency

When Hyde’s highly skilled engineers design blades for your operation, they can spec-match for your operation’s line speed, substrate, and cut precision. They’ll create your blades using custom materials, blade size, blade geometry, coatings, and edge finishes, ultimately providing you with a fully optimized industrial mill blade solution.

Custom mill blades offer numerous tangible benefits that directly impact your operation’s bottom line, including:

- Preventing premature wear

- Preventing misalignment

- Improving cut quality

- Reducing downtime

Of course, a fully custom blade is generally going to cost more than an off-the-shelf option. However, when it comes to industrial operations, it’s a classic case of spending a bit more now to save a lot more in the future.

Let’s Build the Right Mill Knife for Your Operation

At first glance, it can be tempting to think that ‘a knife’s a knife’ and leave it at that. But just one day with Hyde mill knives on your line will change that. Hyde has set the industry standard during our 150-year legacy of family-owned American manufacturing, producing high-performance blades that last longer and cut better than any foreign-made competitor. We’re also proud to provide an unmatched level of comprehensive domestic support, ensuring you always have an expert available who is ready to answer any questions or concerns.

Ready to see how Hyde Industrial Blade Solutions can help your operations become a cut above the rest? Reach out to our team today to get a custom quote!

Share this

- February 2026 (2)

- January 2026 (6)

- December 2025 (4)

- November 2025 (4)

- October 2025 (6)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (2)

- April 2025 (2)

- March 2025 (2)

- February 2025 (1)

- January 2025 (8)

- October 2024 (5)

- September 2024 (3)

- August 2024 (4)

- July 2024 (3)

- June 2024 (1)

- August 2023 (2)

- June 2023 (2)

- March 2023 (1)

- April 2022 (1)

- March 2022 (1)

- January 2022 (1)

- July 2021 (1)

- April 2021 (1)

- March 2020 (1)

- January 2020 (1)

- August 2017 (1)

- May 2017 (2)

- April 2016 (1)

- February 2016 (1)

- January 2016 (1)

- October 2015 (1)