Custom Industrial Blade Manufacturing & OEM Replacements

In addition to the many Hyde brand tools and products we manufacture, Hyde also offers Custom Blade Fabrication – we can design and manufacture to your drawing. If you can think of a knife or machine blade, we can probably make it.

Our Process

Expert Engineering & Reverse Engineering Services

Have a blueprint, CAD file, or just a broken sample? Our engineers work directly with you to reverse engineer obsolete parts or design custom cutting solutions from scratch. We analyze your application to recommend the optimal steel grade and edge geometry.

Prototyping & Material Engineering

From initial CAD modeling to rapid prototyping, we collaborate with your team to optimize blade geometry for your specific application. Our metallurgists analyze wear patterns to recommend high-performance alloys—such as D2, M2, or Tungsten Carbide—that extend blade life and reduce changeover frequency.

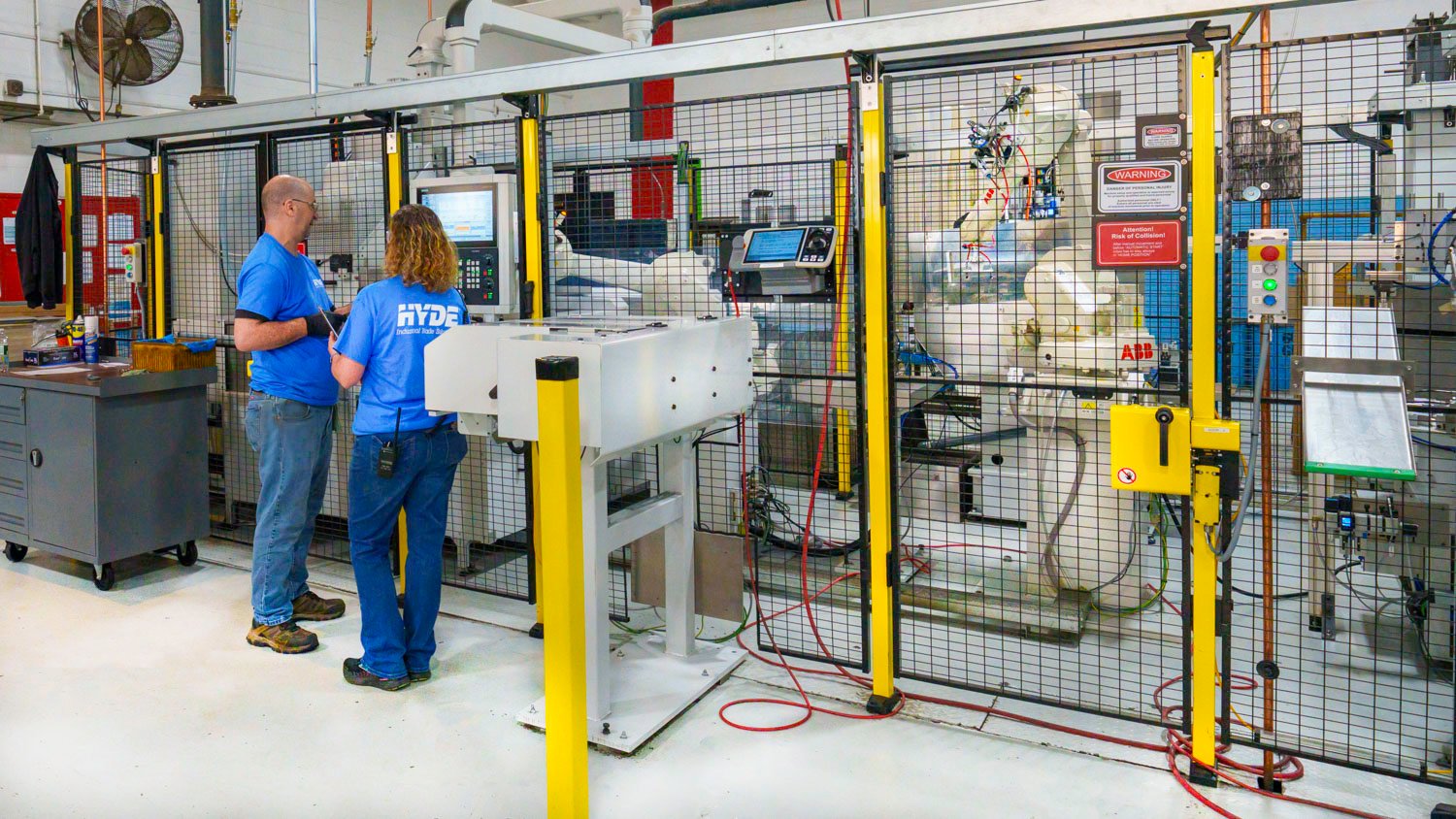

Production & Quality Assurance

We manufacture your custom blades in our ISO 9001 certified facility, utilizing precision grinding and vacuum heat treating to ensure every part meets your exact print specifications. Standard lead times average just 4-6 weeks—significantly faster than OEM replacements.

Hyde Saved a Plastics Processor 10% per year

After dealing with blade life-span issues, a large plastics processor approached Hyde to develop a solution for them.

Our engineering team evaluated their process and blade chemistry to determine a higher grade of blade with stronger abrasion resistance would help.

The outcome, over $60,000 in savings per year, and tool life increases of 45%!

Hyde 5x's Machine Manufacturer's Blade Cuts

A large machine manufacturer approached Hyde to double the lifespan of their current blades from 200,000 to 400,000 cuts.

Our engineering team worked with the customer to develop a longer lasting blade for their machinery.

The results? New blades that last on average 1,100,000 cuts, more than 5x the original blades, resulting in significant gains.

Hyde Decreased Packaging Tears by 95%

A medical device manufacturer had a significant increase in packaging tears after changing plastic suppliers.

Hyde helped develop a new blade for them increasing both the depth and number of cutting slots.

The customer reported back a decrease in 95% of packaging tears, and a return to similar tool life despite the new plastics.

Custom Manufacturing Capabilities & Tolerances

We stock a massive inventory of raw sheet and coil stock—including Stainless, D2, and M2 High-Speed Steel—allowing us to bypass raw material lead times and start grinding your custom order immediately.

- Circular Blade Range: 2” to 54” Diameter (50mm – 1,371mm)

- Straight Knife Range: Up to 70” Length (1,778mm)

- Thickness Capacity: .008” to .750”

- Geometries: Dished, Flat, Toothed, Serrated, & Scalloped.

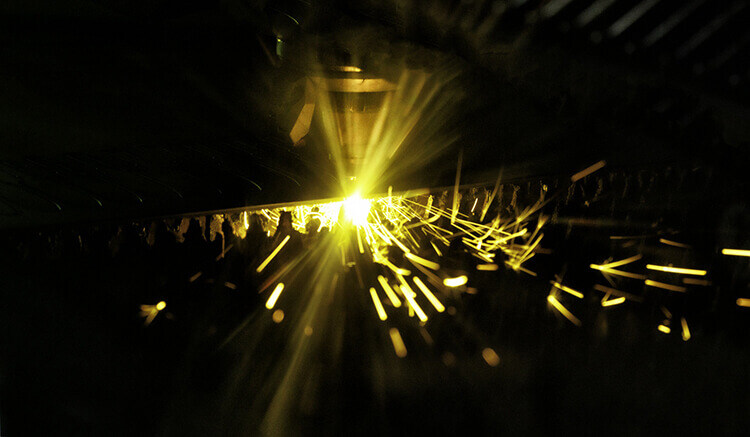

- Processes: Laser Cutting, Blanking, Vacuum Heat Treating, & Surface Grinding.

Whether you need a single prototype or a production run of 10,000 units, our ISO 9001 facility scales to meet your demand.

Get in Touch!

We'd love to help you get a solution based on your needs!